Home > Products > Wood-plastic extrusion mold > Professional Plastic Ceiling Making Machine

Professional Plastic Ceiling Making Machine

- 60 Set / Sets per Month

- Shanghai Dalian Ningbo or negotiated.

- T/T L/C D/P D/A Credit Card

You May Like

Product Details

| Place of Origin | Hubei, China | Brand Name | TianRui | |

| Model Number | TR333 | Shaping Mode | Plastic Extrusion Mould | |

| Product Material | Steel | Product | Household Product |

Product Description

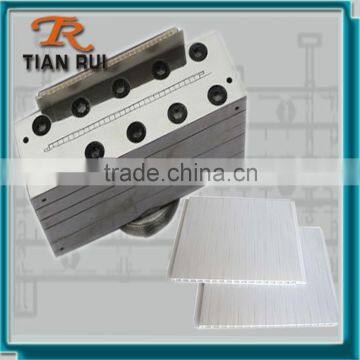

Professional Plastic Ceiling Making Machine

Name | Professional Plastic Ceiling Making Machine |

Size | Various types |

Mould material | 3Cr17, 3Cr17MoNiV,or as per your request |

Mould cavity | 1 or multi-cavity |

Mould composition | Die head, aluminum heating bands, calibrators and water tank |

Feature | Selectable co-extrusion of different raw materials: PVC, PP, PE, ABS Selectable technology: low-foaming, high-foaming & substance co-extrusion Stable discharging, high efficiency, superior quality |

Test | Mould will be tested to get the satisfied sample before delivery |

Service | Provide complete set of production process and technology transfer service |

Lead time | 30 days |

Package | Wooden case for exporting, each mould will be cleaned before packaging. |

Hubei TianRui Professional Plastic Ceiling Making Machine Characters:

The extrusion die head extrusion design:

Use the removable positioning device,making it easier to disassmble.

Precise material flowing control and stable extrusion.

The hidden heating design has increased the brightness of the product surface.

The sp0ecial balance of the pressure holes has lowered the rejection rate.

The extrusion calibrator design:

The automatically adjusting positioning key gives it a precise size.

The tapered design of the calibration sleeve has increased the production speed greatly.

The inlet end is independent vaccum and shapes well.

The camber adjusting device ensures that the line is straight.

Extrusion cooling design:

Double vaccum system promotes the molding.

The combination of eddy current and spray makes it cool fast.

The self adjusting water tank panels are easy to adjust.

The stainless steel frame type system can prevent damage.

The special influent distribuytion gives it a cooling balance.

Application of the Products

Comissioning and after-sales service of mould:mould debugging is one of the most important aspects to ensure

the quality of the mould.The simulation of extrusionprocess conditions for initial commitionin has provide a guarantee for qualified mould before it leaves the factory.The company is equipped with a mould debugging center and advanced extrusion production line.Our skilled commissioning personnel will provide users a full range of services.Over the past decades,we have always provided unremitting after-sales service to our customers,We are willing to cooperate with you sincerely,and to creat the brilliant future together.

If you need any further information, please be free to contact me, we will be very happy to receive your kind message.

Cherry Sindy

Hubei TianRui Plastic Mould Co.,Ltd

Tel: 86-0714-3089139

Fax: 86-0714-3089399

MSN: Chenmo123@

Skype:tr1369999

QQ:921653668

Contact Us

- Hubei Tianrui Plastic Mould Co., Ltd.

- Contact namePeng Lu Chat Now

- Phone86-714-3805111

- AddressNo. 12, Mafang Village, Huangshi Port District, Huangshi, Hubei

Product Categories

New Products

-

Delicate PVC Ceiling Panel Mould

-

Delicate WPC Pillar Extrusion Mould

-

Delicate WPC Extrusion Die for Pillar

-

Timeproof Pillar Extrusion Mould

-

Delicate WPC Pillar Making Machine

-

Delicate Upright Post Extrusion Die

-

Timeproof Upright Post Making Machine

-

Professional PE Wood Plastic Upright Post Extrusion Mold

-

Delicate Upright Post Machine

-

Delicate Upright Post Extrusion Mould

-

Delicate WPC Upright Post Making Machine

-

Delicate WPC Machine for Upright Post

Popular Searches

- plastic mould

- Pc Abs

- Pp Pvc Hdpe Abs

- 3d design

- document

- Agricultural Plastic Products

- plastic injection

- injection moulding

- injection mold

- Plastic Injection Part

- Appliance Part

- injection mould

- extrusion die

- computer plastic mould

- home automation

- Plastic Injection Mould

- Mould Design

- rubber mold

- Automotive Plastic Products

- Molded Product

- Plastic Injection Molding Product

- Injection Moulding Product

- Moulded Product

- Injection Mould Bumper

- Injection Molding

- Household Products Part

- cycle component

- Mould Maker

- rubber flap

- bumper mold

Recommended Products

- epoxy resin cast mould transformer insulator manufacture APG process chinese manufacture

- Epoxy Resin Injection APG Moulding die casting mold

- Multi Cavity Custom plastic injection mold for Switch socket plug

- PET Multi Cavity Custom plastic injection mold

- Custom Overmolding/2k plastic Injection mold Two-Shot Plastic Mold

- Custom Plastic Mold for TV Backplate Cover White Goods

- Custom Plastic Injection Mold for Sweeper Housing

- Custom Plastic Injection Mold for Router with 3C

- Custom Plastic Mold for Hair Dryer

- Custom Plastic Household Mold for Coffee Pot Handles

- Custom Plastic Injection Mold for 3D Printer Housing-Injection Molding Service

- Custom PVC Plastic Mold for Threaded Pipe Fittings Multi Cavity Injection Molding

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mould > Plastic Mould

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Peng Lu

Hi there! Welcome to my shop. Let me know if you have any questions.

Peng Lu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile